Are Forgings Stronger than Castings and Weldments?

For centuries, metal manufacturing processes have been relied on by a number of industries. From transportation and power generation to valves and pipeline equipment, metal manufacturing processes like casting, forging, and welding. In today’s blog, we’ll compare these three popular metal processes and discuss how forging remains unmatched.

Common Applications of Closed Die Forgings

At CanForge, we’re committed to delivering superior forgings for all facets of the market, including closed die forgings. Closed die forgings can be used in a wide variety of applications, from automotive and aerospace to agriculture and mining.

Why Choose Rolled Rings

At CanForge, we produce a wide variety of high-quality forgings for a whole host of demanding and sophisticated engineering applications. In today’s blog, we’ll be discussing the many functions of rolled rings, how they’re manufactured and why CanForge’s seamless rolled rings always come out on top.

How the carbon content of steel affects forgeability

Your guide to forgeability, steel, and carbon content. Read more about how the amount of carbon in steel impacts forging and related products we offer.

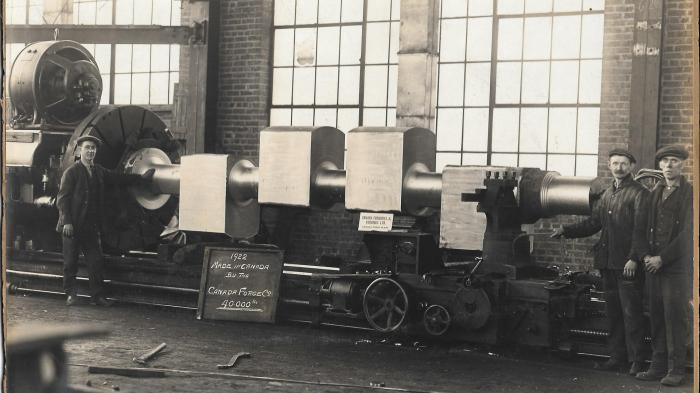

The History of CanForge

Originally founded in 1912, the Canadian-owned custom forging producer has grown to supply quality and specialty forgings to a wide variety of companies across the United States and Canada. And just like superheroes, our origin story is a tale that should be told.

The Equipment We Use to Provide High-Quality Forgings

At CanForge we use a variety of equipment to create our high-quality forgings–from hammers and presses to upsetters and ring rollers.

Understanding the different forging processes

Forging is the process of forming and shaping metals through the use of hammering, pressing or rolling. Here at CanForge, we utilize a variety of different forging techniques, each of which carries its own benefits. Generally, though, there are four recognized forging processes.

Monel®: the nickel-copper alloy with excellent corrosion resistance

At CanForge, we produce forgings for the most demanding and sophisticated industries. One of the superior materials we utilize at Canada Forgings Inc is Monel®. In today’s blog, we’ll explore what makes Monel® a top choice for many of our forgings.

Spotlight On the Pulp and Paper Industry

With graphic paper demand declining worldwide, the pulp and paper industry has been undergoing quite a transformation. The industry is growing in other directions thanks to an increased demand for plastic-free packaging.

The Power of Testing

We offer several testing measures to assure our customers that our forgings meet their expectations. Whether we’re forging stainless steel, aluminum, or titanium, these tests guarantee that the products will sustain the environment for which they were designed.