The production of seamless forged rings is often performed by a process called ring rolling on rolling mills. These mills vary in size to produce rings with outside diameters of just a few inches to over 300 inches and in weights from a single pound up to over 300,000 pounds.

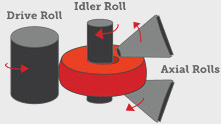

The process starts with a circular preform of metal that has been previously upset and pierced (using the open die forging process) to form a hollow “doughnut.” This doughnut is heated above the re-crystallization temperature and placed over the idler or mandrel roll. This idler roll then moves under pressure toward a drive roll that continuously rotates to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the resulting ring.

Seamless rings can be produced in configurations ranging from flat, washer-like parts to tall, cylindrical shapes, with heights ranging from less than an inch to more than 9 feet. Wall thickness to height ratios of rings typically range from 1:16 up to 16:1, although greater proportions can be achieved with special processing. The simplest and most commonly used shape is a rectangular cross-section ring, but shaped tooling can be used to produce seamless rolled rings in complex, custom shapes with contours on the inside and/or outside diameters.

The Seamless Rolled Ring Forging Process

Producing a ring "preform" by the open die forging process:

- Rough forging a heated billet between flat dies to the maximum diameter dimensions, then upset to achieve structural integrity and directional grain flow.

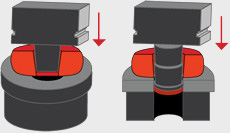

- Work piece is punched, then pierced to achieve starting “doughnut” shape needed for ring rolling process..

- Completed preform is ready for placement on ring mill for rolling.

Rolled Ring Forging Process:

- Ring rolling process begins with the idler roll applying pressure to the preform against the drive roll.

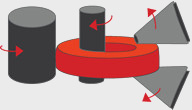

- Ring diameters are increased as the continuous pressure reduces the wall thickness. The axial rolls control the height of the ring as it is being rolled.

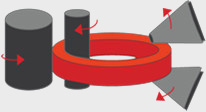

- The process continues until the desired size is achieved.

Learn more about Seamless Rolled Ring Products Learrn More about Mandrel Ring Products