Grain Flow During Metalworking: Why It’s Important for Forging

Forging is as much a skill as it is an art. For more than 6,000 years, forging techniques have evolved with one key goal in mind: to advance what forged components can do. While some of these advancements are evident in the forging technology we use today, other techniques are less noticeable to the naked eye - but no less essential. Grain flow is one of them.

Let’s explore why grain flow is an important part of the forging process and how CanForge utilizes this to ensure reliable and superior quality in our forged products.

What is Grain Flow?

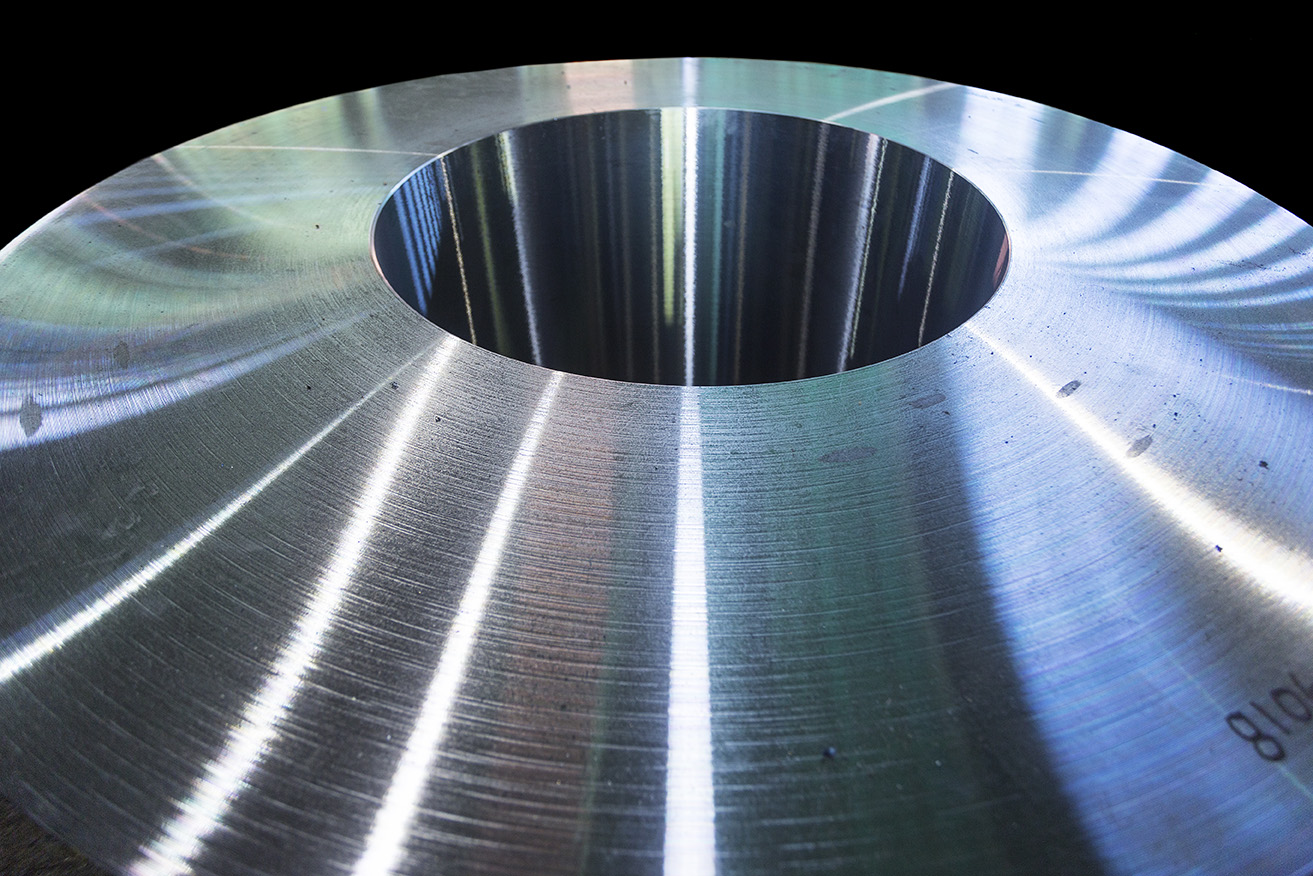

Every piece of metal has a grain structure determined by the material it is made from and how it is processed. Though we cannot see the structure without using a microscope, these tiny crystallized grains have a big impact on the quality of a metal component.

During the metalworking process, the grains of the forged metal are heated and cooled to create an optimal grain structure that is directional. We refer to this as grain flow, where the grains are manipulated so they are aligned throughout the metal component.

Unlike other forms of metal-forming like  , forging techniques allow for the grain flow to be optimized. In the casting process, metal is poured into a mold, but this method does not allow the grains to form a uniform structure. As a result, when the piece cools, the structure appears more random as grains are of different sizes. Gaps form between the grains due to the scattered structure.

, forging techniques allow for the grain flow to be optimized. In the casting process, metal is poured into a mold, but this method does not allow the grains to form a uniform structure. As a result, when the piece cools, the structure appears more random as grains are of different sizes. Gaps form between the grains due to the scattered structure.

In contrast, forging techniques like hammering apply pressure to the component and change the grain structure. The grains are brought in tight together, thus reducing the gaps found in the grain structure of casted metal components.

Why is Grain Flow Important for Forging?

So why do we go through the added effort of creating grain flow?

Because it is a game-changer for creating components that can withstand high-stress applications. Grain flow improves impact and fatigue resistance, making forged components less likely to fracture or crack when in use. These components also have better ductility that enables them to undergo physical changes to their shape without breaking apart.

This durability and strength are why forged components are the best choice for demanding industries, including power generation, defence and aerospace. Our customers can’t afford to have their machinery and equipment break down due to parts that aren’t reliable, which is why they rely on CanForge for high-quality forged components.

Reach out to us to learn more about the forged products we can supply for your business.